条码标签纸的选择与使用:提升工作效率的小技巧

尕枯非生

2024-10-11 21:26:49

0次

条码标签纸的选择与使用:提升工作效率的小技巧

在现代化办公和工业生产中,条码标签纸已经成为不可或缺的一部分。正确的选择和使用条码标签纸能够显著提高工作效率。以下就条码标签纸的选择与使用提供一些小技巧。

一、条码标签纸的选择

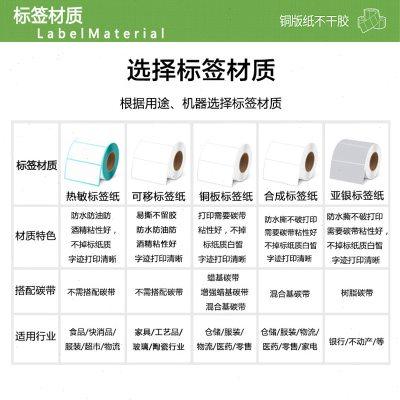

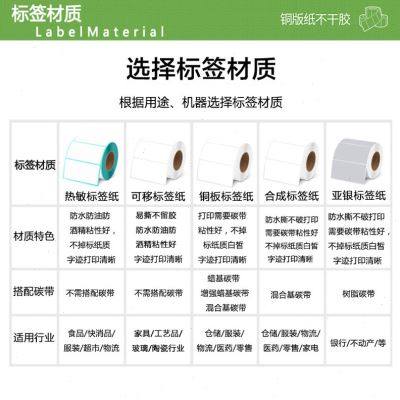

1. 材质选择:条码标签纸的材质多种多样,如纸质、聚酯(PET)等。选择时需根据使用环境和使用需求来定。如需要防水防油防刮的标签,则需选择特殊材质的标签纸。

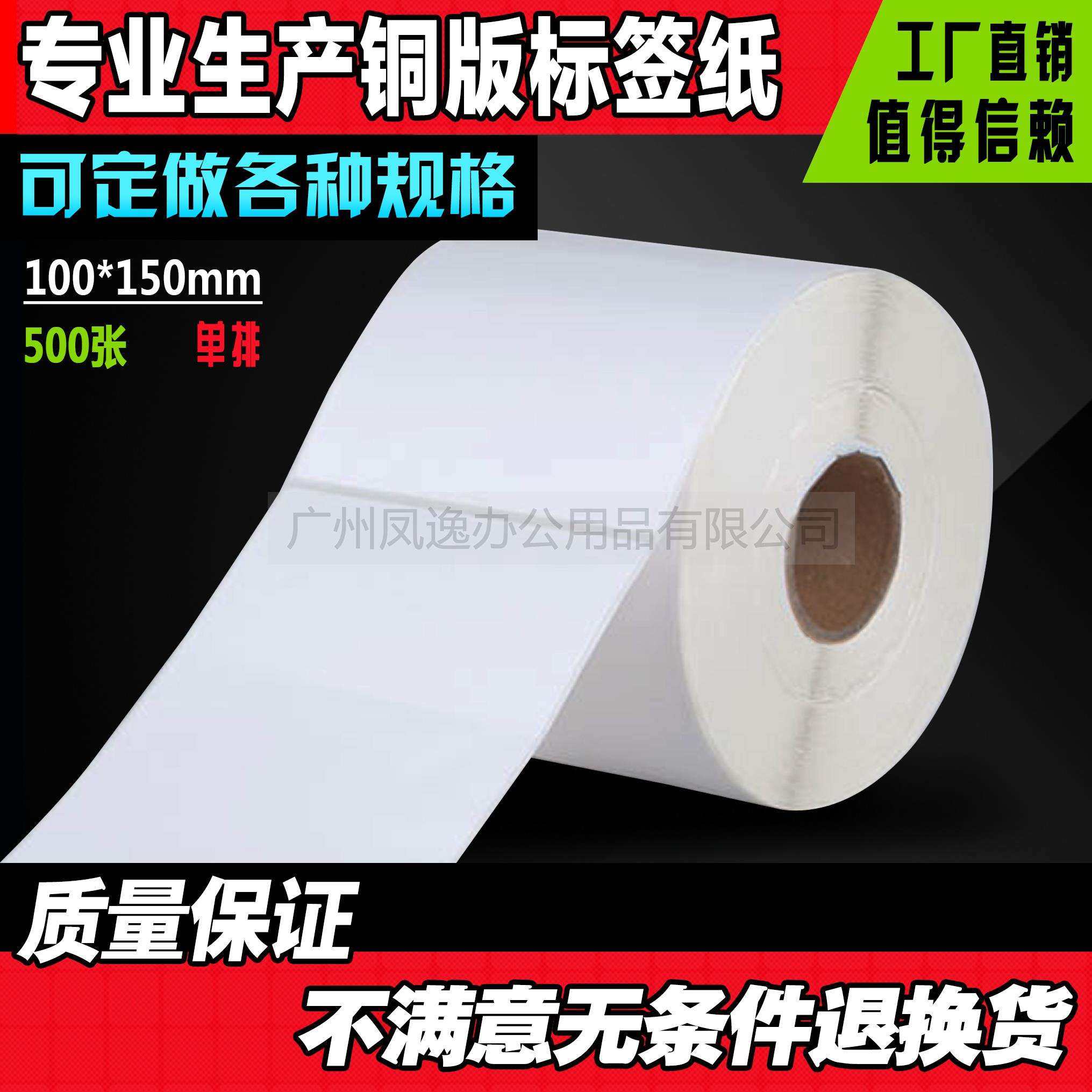

2. 大小选择:根据需要打印的内容和条码的密度,选择合适大小的标签纸。过大的标签纸不仅浪费资源,还会影响工作效率。

3. 颜色选择:标签的颜色应根据背景色和阅读设备的要求来选择,一般建议选择对比度高、易于识别的颜色。

二、条码标签纸的使用

1. 设计打印:利用专业的条码打印软件进行设计,保证条码的清晰度和可读性。避免在标签上添加过多不必要的信息,以免影响扫描速度。

2. 粘贴位置:根据实际需要,将标签粘贴在产品或包装的合适位置。应确保标签在运输、存储和使用过程中不易脱落或损坏。

3. 定期更换:定期更换旧的标签,保证产品的信息始终保持最新状态。对于需要追踪的产品,定期更换标签能更好地掌握其动态。

三、提升工作效率的小技巧

1. 批量打印:将需要打印的标签进行批量处理,减少单次打印的次数,提高工作效率。

2. 预先备货:根据生产计划和库存情况,预先备好一定数量的标签纸,避免因缺货而影响生产进度。

3. 合理使用软件:利用专业的条码管理软件进行标签的设计、打印、跟踪和管理,实现信息的高效传递和处理。

4. 定期培训:对员工进行条码标签纸的选择、使用及管理等方面的培训,提高员工的工作效率和工作质量。

翻译成英文如下:

Barcode Label Paper Selection and Use: Tips to Improve Work Efficiency

In modern office and industrial production, barcode label paper has become an indispensable part. The correct selection and use of barcode label paper can significantly improve work efficiency. Here are some tips for selecting and using barcode label paper. I. Barcode Label Paper Selection 1. Material selection: There are various materials for barcode label paper, such as paper and polyester (PET). The selection should be based on the usage environment and requirements. If labels that are waterproof, oil-resistant, and scratch-resistant are needed, special material labels should be chosen. 2. Size selection: Choose the appropriate size of label paper based on the content to be printed and the density of the barcode. Overly large label paper not only wastes resources but also affects work efficiency.3. Color selection: The color of the label should be selected based on the background color and the requirements of the reading device. Generally, it is recommended to choose a color with high contrast and easy to identify.

II. Barcode Label Paper Use 1. Design and printing: Use professional barcode printing software to design and ensure the clarity and readability of the barcode. Avoid adding too much unnecessary information to the label, which may affect scanning speed. 2. Paste position: Paste the label at a suitable position on the product or packaging according to actual needs. Ensure that the label is not easy to fall off or damage during transportation, storage, and use. 3. Regular replacement: Regularly replace old labels to ensure that product information always remains up to date. For products that require tracking, regular label replacement can better grasp their status. III. Tips to Improve Work Efficiency 1. Batch printing: Batch process the labels that need to be printed to reduce the number of single prints and improve work efficiency. 2. Pre-stocking: Pre-stock a certain amount of label paper based on production plans and inventory to avoid affecting production progress due to stockouts. 3. Rational use of software: Use professional barcode management software for label design, printing, tracking, and management to achieve efficient information transmission and processing. 4. Regular training: Provide training on the selection, use, and management of barcode label paper for employees to improve their work efficiency and quality.相关内容

热门资讯

揭秘条码标签纸:功能、特点及适...

条码标签纸是一种用于打印条形码和二维码的纸质材料,广泛应用于零售、物流、医疗、制造等行业,具有耐用、...

解锁条码标签纸的多样应用场景

条码标签纸具有广泛的应用场景和价值,可应用于零售、物流、医疗、生产制造等多个行业,实现快速识别、管理...

条码标签纸:办公耗材中的必备利...

条码标签纸是办公耗材中不可或缺的利器,适用于多领域,可快速准确记录和识别信息,提高效率和数据安全性,...

提升效率:条码标签纸在办公流程...

条码标签纸在办公流程中扮演重要角色,能自动化追踪、快速识别分类、减少错误率、管理库存、增强可读性、适...

条码标签纸的选购指南:提升办公...

选购条码标签纸需明确需求,考虑材质、尺寸、粘性、抗污性和兼容性等因素,选择知名品牌和合适价格,并注意...

解析条码标签纸:如何成为现代办...

条码标签纸在办公中,快速、准确管理物品信息。选材合理,设备解析迅速,配合软件可高效管理物品信息,并培...

探索条码标签纸的多样化用途与优...

条码标签纸在零售、物流、资产管理、医疗保健和工业制造等领域具有多样化用途,其优势包括高效性、准确性、...

选购指南:如何选择适合你的条码...

选购条码标签纸需考虑使用环境、条码类型、标签尺寸形状、材质、成本效益及品牌质量。选择适合的标签纸能提...

条码标签纸的印制技术及优势分析

文章摘要:本文介绍了条码标签纸的印制技术,包括印刷、涂层处理和条码打印等环节,并分析了其高质、耐用、...

办公室中的小助手:条码标签纸的...

条码标签纸是办公室中的小助手,可进行物品标识、资产管理、库存管理、快递与邮件管理及会议活动标识,提高...