办公耗材中,条码标签纸的质量选择及保养技巧

尕枯非生

2024-11-04 00:52:53

0次

办公耗材中,条码标签纸的质量选择及保养技巧

一、质量选择

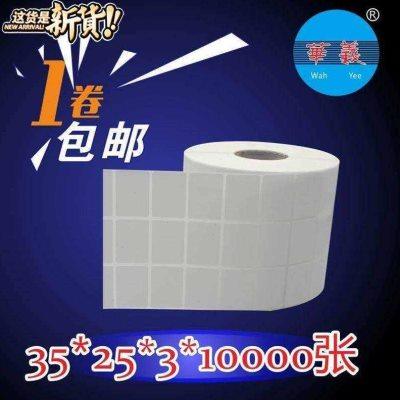

在办公耗材中,条码标签纸是不可或缺的一部分。选择高质量的条码标签纸对于确保打印效果、使用持久性和成本控制至关重要。以下是选择条码标签纸时需考虑的几个关键因素:

1. 材料质量:优质的条码标签纸通常采用耐磨、耐撕、耐水等特性较强的材料制成,能够适应各种恶劣环境。

2. 粘性:标签纸的粘性也很重要,过强或过弱的粘性都会影响标签的使用效果。高质量的标签纸应具备适中的粘性,既能牢固粘贴在物品表面,又不会轻易脱落。

3. 颜色和清晰度:标签的颜色和清晰度直接影响条码或文字的可读性。选择颜色鲜艳、印刷清晰的标签纸可以确保扫描设备准确读取信息。

4. 尺寸和形状:根据实际需求选择合适的尺寸和形状,避免浪费和不必要的成本。

二、保养技巧

除了选择高质量的条码标签纸外,正确的保养方法也能延长其使用寿命。以下是几条保养技巧:

1. 避免长时间暴露在阳光下:长时间暴露在阳光下会导致标签纸褪色、变形,影响使用效果。因此,应将标签纸存放在阴凉干燥的地方。

2. 避免与化学物质接触:某些化学物质可能会对标签纸产生腐蚀作用,导致标签变形、脱落。因此,存放和使用时应避免与化学物质接触。

3. 定期清洁打印机:打印机的清洁度直接影响标签的打印效果。定期清洁打印机可以确保打印出的标签清晰、无污渍。

4. 正确使用和粘贴:在使用和粘贴标签时,应遵循正确的操作方法,避免损坏标签或粘贴不当导致脱落。

The Skills of Quality Selection and Maintenance for Barcode Label Paper in Office Consumables

In office consumables, barcode label paper is an indispensable part. Selecting high-quality barcode label paper is crucial for ensuring printing results, durability, and cost control. Here are several key factors to consider when selecting barcode label paper:

1. Material Quality: High-quality barcode label paper is usually made of materials with strong resistance to wear, tear, and water, able to adapt to various harsh environments.

2. Adhesion: The adhesive property of label paper is also important. Excessive or insufficient adhesive strength can affect the usage effect of the label. High-quality label paper should have moderate adhesive strength, which can firmly adhere to the surface of the object without easily falling off. 3. Color and Clarity: The color and clarity of labels directly affect the readability of barcodes or text. Selecting label paper with bright colors and clear printing can ensure that scanning devices accurately read information. 4. Size and Shape: Choose the appropriate size and shape according to actual needs to avoid waste and unnecessary costs. Maintenance Skills: 1. Avoid prolonged exposure to sunlight: Prolonged exposure to sunlight can cause label paper to fade and deform, affecting its usage effect. Therefore, label paper should be stored in a cool and dry place. 2. Avoid contact with chemicals: Certain chemicals may corrode label paper, causing deformation or peeling off. Therefore, label paper should be stored and used away from chemicals. 3. Regularly clean the printer: The cleanliness of the printer directly affects the printing effect of labels. Regularly cleaning the printer can ensure that the printed labels are clear and without stains. 4. Correct usage and application: When using and applying labels, follow the correct operating methods to avoid damaging the labels or improper application that leads to peeling off.相关内容

热门资讯

揭秘条码标签纸:功能、特点及适...

条码标签纸是一种用于打印条形码和二维码的纸质材料,广泛应用于零售、物流、医疗、制造等行业,具有耐用、...

解锁条码标签纸的多样应用场景

条码标签纸具有广泛的应用场景和价值,可应用于零售、物流、医疗、生产制造等多个行业,实现快速识别、管理...

条码标签纸:办公耗材中的必备利...

条码标签纸是办公耗材中不可或缺的利器,适用于多领域,可快速准确记录和识别信息,提高效率和数据安全性,...

提升效率:条码标签纸在办公流程...

条码标签纸在办公流程中扮演重要角色,能自动化追踪、快速识别分类、减少错误率、管理库存、增强可读性、适...

条码标签纸的选购指南:提升办公...

选购条码标签纸需明确需求,考虑材质、尺寸、粘性、抗污性和兼容性等因素,选择知名品牌和合适价格,并注意...

解析条码标签纸:如何成为现代办...

条码标签纸在办公中,快速、准确管理物品信息。选材合理,设备解析迅速,配合软件可高效管理物品信息,并培...

探索条码标签纸的多样化用途与优...

条码标签纸在零售、物流、资产管理、医疗保健和工业制造等领域具有多样化用途,其优势包括高效性、准确性、...

选购指南:如何选择适合你的条码...

选购条码标签纸需考虑使用环境、条码类型、标签尺寸形状、材质、成本效益及品牌质量。选择适合的标签纸能提...

条码标签纸的印制技术及优势分析

文章摘要:本文介绍了条码标签纸的印制技术,包括印刷、涂层处理和条码打印等环节,并分析了其高质、耐用、...

办公室中的小助手:条码标签纸的...

条码标签纸是办公室中的小助手,可进行物品标识、资产管理、库存管理、快递与邮件管理及会议活动标识,提高...